About this project

The Graduation Internship project was conducted at Applied Micro Electronics “AME” BV, a leading developer and manufacturer of high-quality electronic products in Brainport Eindhoven. The focus of the internship was on predictive maintenance for Pick & Place (P&P) nozzles used in the electronics manufacturing process. These nozzles are critical for accurately placing surface-mounted devices (SMD) onto printed circuit boards, and their degradation can lead to costly failures and manual rework.

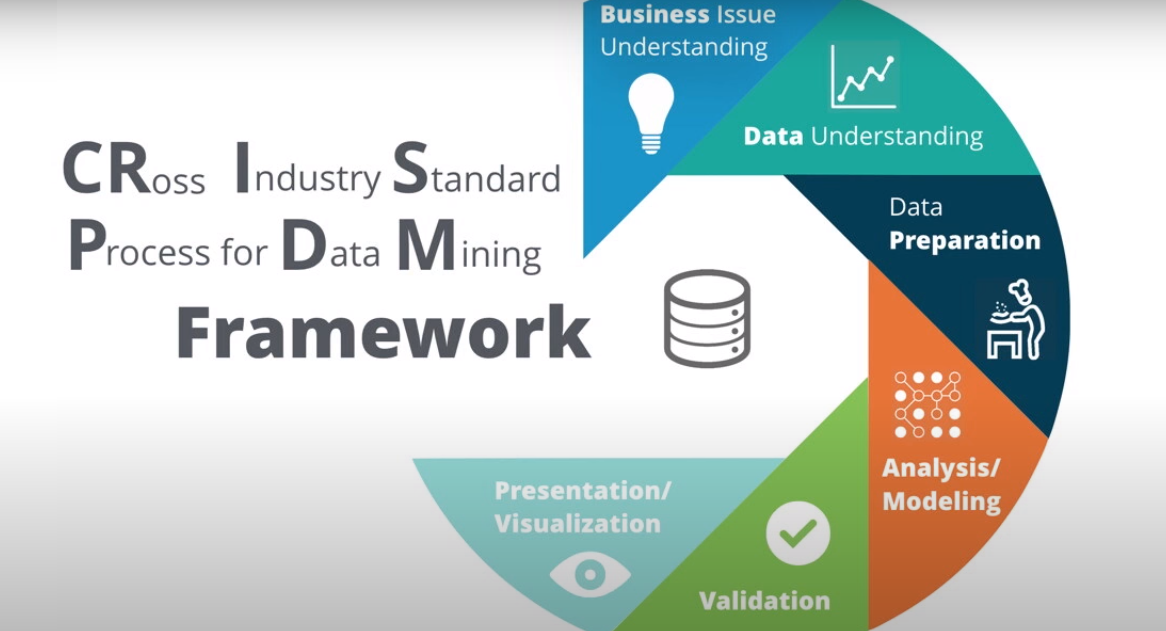

The main objective was to develop a machine learning model capable of predicting nozzle failures before they occur, enabling proactive maintenance and reducing downtime. The project followed the CRISP-DM methodology, encompassing business understanding, data collection and preparation, model development, evaluation, and, if possible, deployment. This approach ensured a thorough understanding of the manufacturing process, high-quality data analysis, and the creation of a robust predictive solution to improve operational efficiency at AME.

Key Features

- Predictive maintenance ML

- Pick & Place machines

- CRISP-DM methodology

- Reduced downtime and manual rework

- Data-driven decision making